Low cost per transported ton

We build our trailers as compact as possible with efficient use of width and height. This gives you a smooth trailer and efficient logistics.

The right equipment for the right job

On all our wagons with the MetaQ system, you can change the container/ flatbed, and in this way use the chassis all year round for harvesting, dumper, manure driving, machine moving and bale transport. In changing the body, the chassis is raised 35 cm with the hydraulic suspension and the axles in the tip joints are loosened. Tool legs are placed in the container body and the chassis is then lowered. Ready for change.

Low own-weight

We construct your body with the best materials in some of Europe's largest industrial machines. For example, almost all containers are built in Brinell 450 (Hardox). This gives us low net weight but high load capacity, which is proven in independent studies that find that our system has approx. 25% less fuel consumption and approx. 50% lower soil compaction compared to conventional systems.

Maneuverability and efficiency

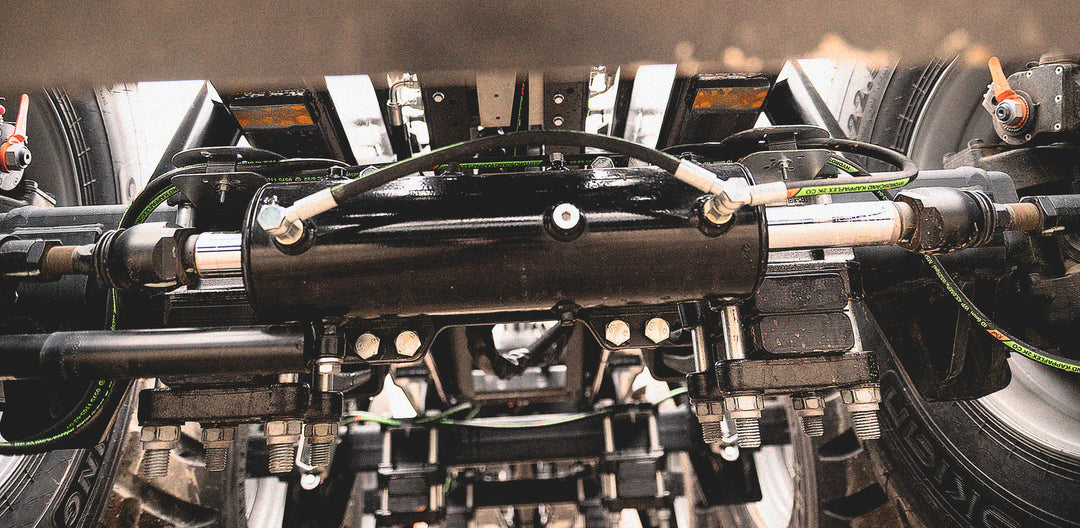

We laser align our BPW axles for optimal compliance, reduced tire wear and fuel consumption. It is proven in independent studies that our system has approx. 25% less fuel consumption and approx. 50% lower soil compaction compared to conventional systems.

Comfort and stability

Our hydraulic axle suspension with communicating vessel technology has a wide base and a stable ride. At Metsjö, we are also masters at building our trailers low.

Large wheels within legal width

Accessibility

Our focus on agriculture has meant that over the years we have developed a construction that enables really large wheels within the legal width

Maximized maneuverability

Rear steering axle is standard on our larger wagons, the axle straightens when you put pressure on it. Front steering axle can be added.

You can upgrade the steering to manual forced steering, where you can force the axle with the tractor's hydraulic controls.

Or upgrade to fully automatic steering that acts proportionally to the trailers speed.