Low cost per transported ton

We build our trailers as compact as possible with efficient use of width and height. This gives you a smooth trailer and efficient logistics.

Low own-weight

We construct your trailers with the best materials in some of Europe's largest industrial machines. For example, most trailers have wear surfaces built in Brinell 450 (Hardox). This gives us low own weight but high load capacity, which is proven in independent studies that find that our system has approx. 25% less fuel consumption and approx. 50% lower soil compaction compared to conventional systems.

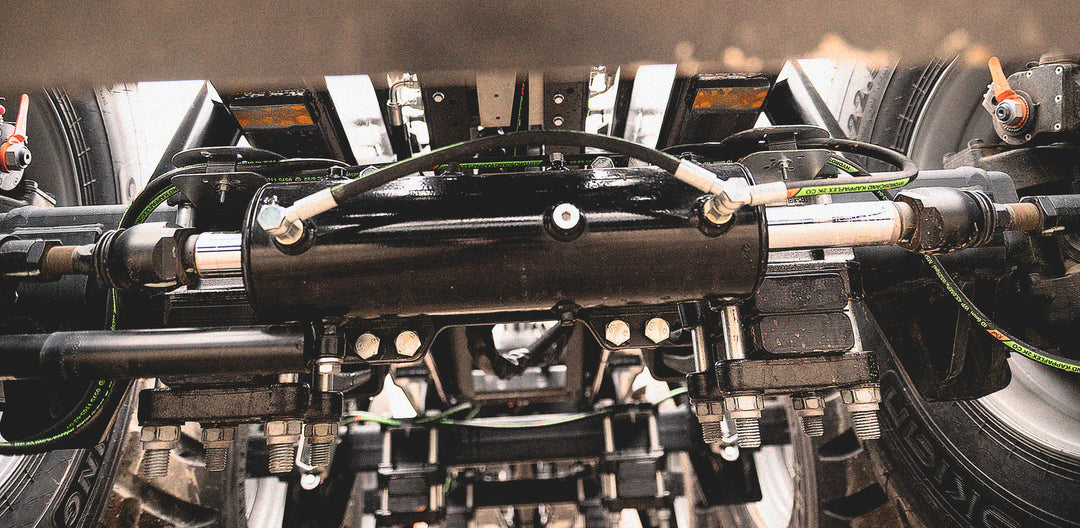

Maneuverability and efficiency

We laser align our BPW axles for optimal compliance, reduced tire wear and fuel consumption. It is proven in independent studies that our system has approx. 25% less fuel consumption and approx. 50% lower soil compaction compared to conventional systems.

Komfort och stabilitet

Vår hydrauliska axelupphängning med kommunicerande kärlteknik har en bred bas och en stabil gång. På Metsjö är vi dessutom mästare på att bygga våra vagnar låga.

Stora hjul inom laglig bredd

Framkomlighet

Vårt fokus på lantbruket har gjort att vi med åren utvecklat en konstruktion som möjliggör riktigt stora hjul inom laglig bredd.

Följsamhet och skonsamhet

Styrande axel bak är standard på våra större vagnar och kan annars väljas som tillval, axeln rätas när man sätter tryck på den.

Man kan uppgradera styrningen till manuell tvångsstyrning där man kan forcera axeln med traktorns hydraulreglage.

Eller uppgradera till helt automatisk styrning som agerar proportionellt med vagnens hastighet.